CoolSiC™ - revolution to rely on in high voltage segments

Silicon Carbide (SiC) devices belong to the so-called wide band gap semiconductor group. They offer a number of attractive characteristics for high voltage power semiconductors when compared to commonly used silicon (Si). In particular, the much higher breakdown field strength and thermal conductivity of SiC allow creating devices which outperform by far the corresponding Si ones. This way you can reach unattainable efficiency levels in your designs.

Silicon carbide (SiC) has a wide bandgap of 3 electronvolt (eV) and a much higher thermal conductivity compared to silicon. SiC based MOSFETs are most suited for high breakdown, high power applications that operate at high frequency. Compared to silicon, the device parameters such as for example the RDS(on) change less with temperature. This allows designers to work within tighter margins in their designs, allowing extra performance to be delivered. Based on proven, high quality volume manufacturing, Infineon’s CoolSiC™ solutions combine revolutionary technology with benchmark reliability – for our customers’ success today and tomorrow.

The use of SiC based power semiconductor solutions has shown a huge increase over the last

years, it is a revolution to rely on. Driving forces behind this market development are the following trends: energy saving, size reduction, system integration and improved reliability.

The combination of a fast silicon based switch with a SiC diode – is often termed a

“hybrid” solution. In recent years Infineon has manufactured several millions of hybrid modules and has seen them installed in various customer products.

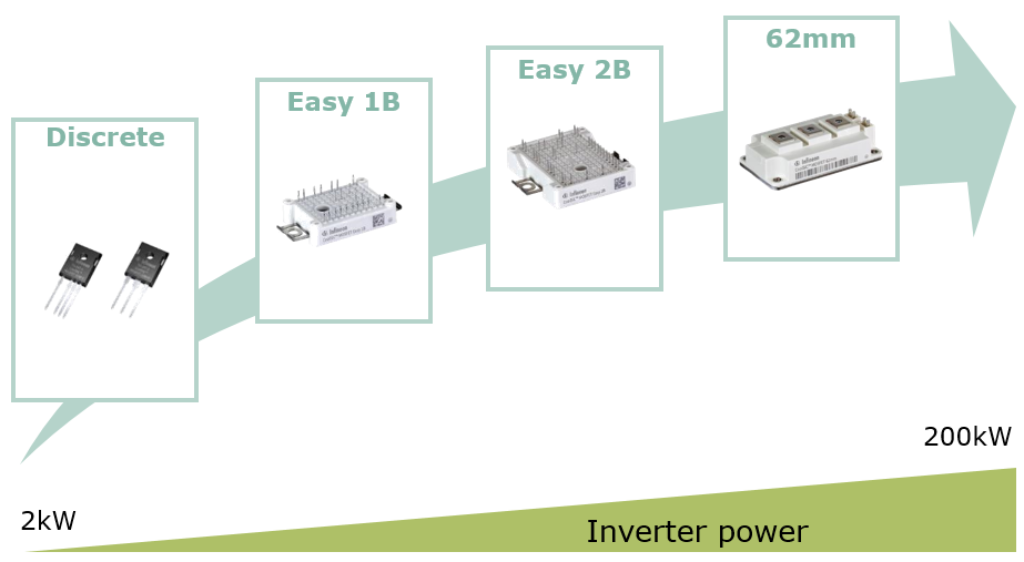

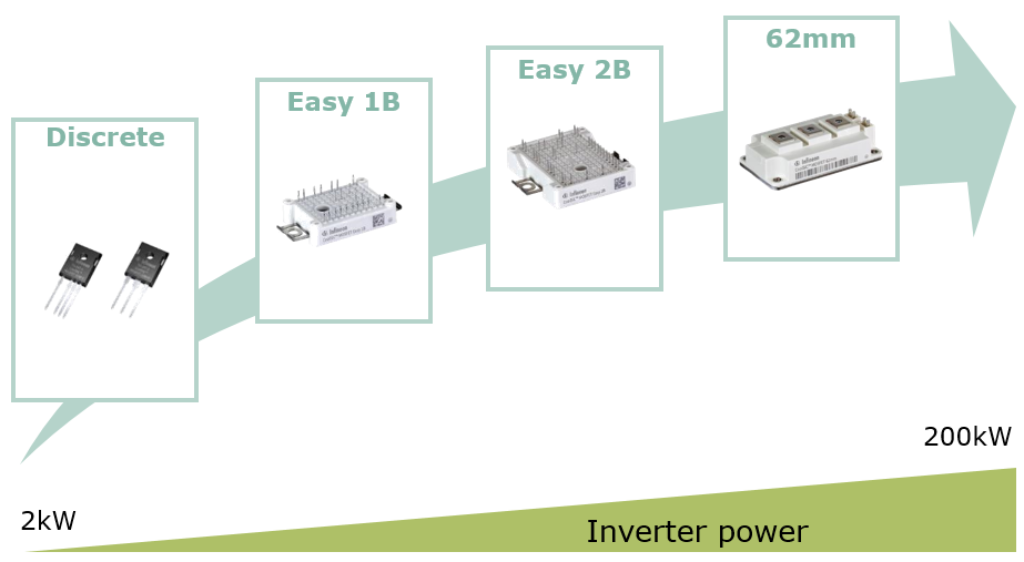

Over the next few years, SiC solutions will expand into other application fields such as industrial or traction drives. The reasons for this are the market forces pushing for loss reduction, not only for the sake of improved efficiency but also for smaller packages – resulting from reduced heat sink requirements. As shown in figure above, SiC is already being used for high end and niche

solutions. Today’s designs use these benefits to reduce system cost in specific application areas.

|

Addto My favority hello,welcome to HK WinworldTech Website !

Addto My favority hello,welcome to HK WinworldTech Website !